WHAT WE CAN DO FOR YOU

TERMINAL

HANDLING OF LOADING UNITS IN COMBINED TRANSPORT (ROAD-RAIL)

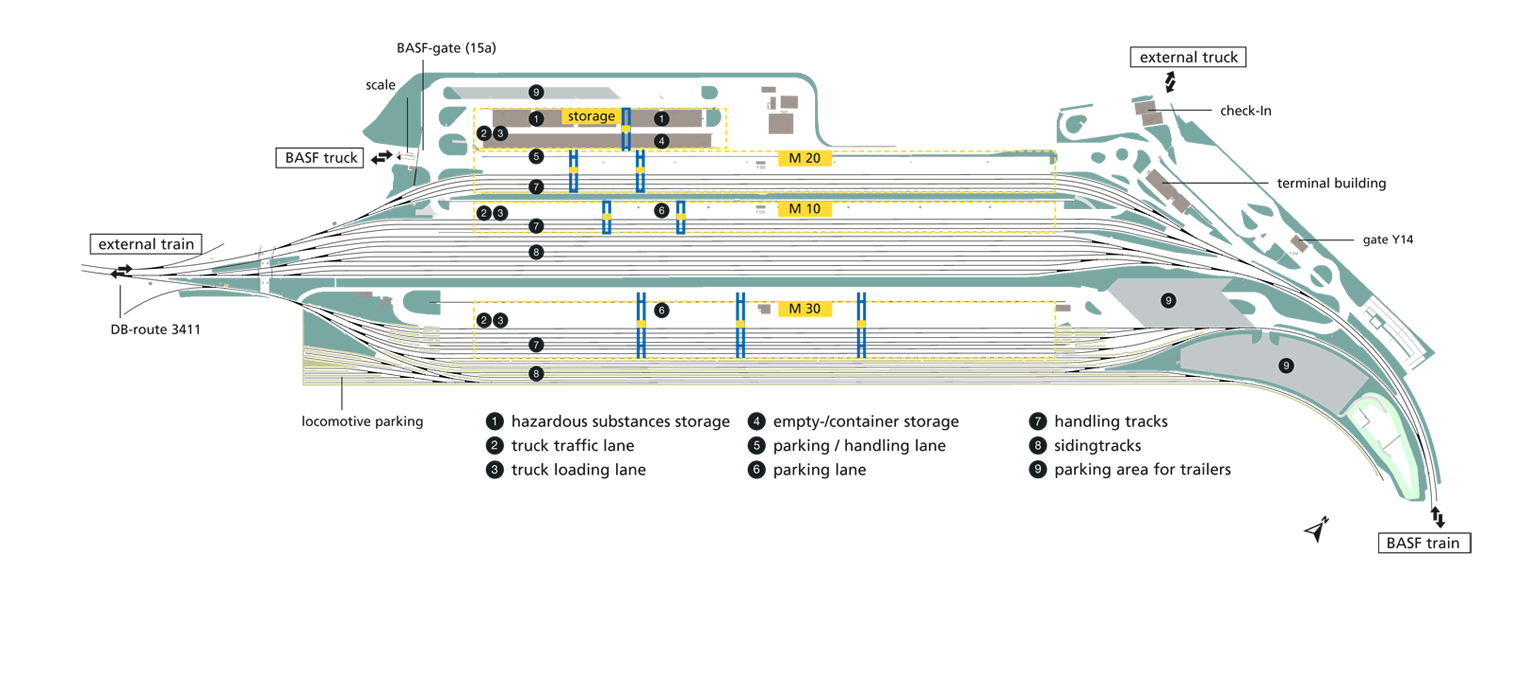

As one of the largest inland terminals in Europe, KTL works in a so-called flow process, which means that the tracks under the crane are mostly occupied several times within 24 hours. This is supported by an intelligent terminal operating system. KTL’s control center also takes over train formation tasks for the respective railway companies and tries to compensate for any incoming train delays by planning the most flexible track occupancy possible. With uninterrupted business hours from Monday 05.00h to Saturday 13.00h, KTL meets the customers‘ desire for access to the loading units as continuous as possible.

SERVICES

- Transshipment road/rail, rail/rail and rail/road

- Interim storage of empty and loaded loading units (e.g. bulk containers up to 20′-45′, also swap versions; Box container 20′-45′; Swap bodies 7.15-7.82 m; Semi-trailers up to 13.60 m, also mega trailers) incl. EDP parking space management

- Control of the loading units with a computer-assisted check-in and check-out system

- Attaching and removing dangerous goods labels to loading units

- Platform of services for railway transport companies (e.g. damage assessment and damage documentation, management of damaged and buffer wagons)

CONTACT

- Area: 300.000 m²

- Storage capacity: approx. 2650 TEU (20′ container units)

- 9 transshipment tracks, 620 m cranable length each (module 10 and module 30)

- 4 transshipment tracks, 564 m cranable length each (module 20)

- 12 sidings, 600-700 m length each

- 7 gantry cranes (manufacturer Künz, A – Hard), payload 40 t each

Further services upon request.

TRUCKING

TRUCK-TRANSPORTS FOR PRE- AND ON- CARRIAGE

As the trucking department of KTL GmbH, we complete the terminal services and offer pre-carriage and on-carriage transports in combined transport.

Our top modern fleet consists of tractor units and trailers that meet the highest quality standards. All of our semitrailer tractors are ADR-approved and can transport any type of tank- and box container.

We have experience of over 20 years in the field of pre-carriage and on-carriage transports, local and long-distance transports, as well as in internal transports in conjunction with the BASF loading points.

SERVICES

- Loading and unloading of all bulk and box containers used in Europe and overseas, swap bodies and semi-trailers before and after rail transport (combined trucking)

- Loading and unloading from and to BASF with standardized processes

- Scheduling in consultation with the loading and unloading points

- On-time IT-supported vehicle scheduling

- Cleaning cycles at nearby tank-cleaning facilities

- BBS driver training by master drivers, especially for ADR transport and load securing

- High competence in the transport of dangerous goods of all classes

- SQAS-Assessment

- Own trucks and drivers

- Integrated subcontractors

- ISOPA certificate

- From the end of 2023 use of electric trucks for emissions and CO2 neutral pre carriage from KTL

CONTACT

FLEET

- Tractor units with ADR approval for classes 2-6 and 8-9

- Container chassis for 20 – 45′ bulk and box containers, also for high cube containers up to 45′, also with ADR approval

- Container – side loader for 20′ – 45′ containers

- Supercharged vehicles (liquid)

- Vehicles with tipping chassis

- Our fleet is staffed in multiple shifts and is therefore available around the clock

- Electric trucks and terminal trucks from the end of 2023 on

DISPOSITION

- Mo 05:00 – 24:00h, Tue – Fr 00:00 – 24:00 Uhr and Sat until 13:00h

CONTAINER STORAGE

STORAGE OF HAZARDOUS MATERIALS AND EMPTY CONTAINERSN

On our company premises, we have extensive capacities for various types of storage for top cranable and stackable tank- or box containers.

This includes a hazardous material container warehouse with hazardous material tubs for loaded containers with hazardous materials or water hazard class, a storage area for loaded containers with harmless goods or empty containers (including empty and uncleaned containers ex hazardous materials).

Our services ensure smooth and safe storage.

The loading units in our hazardous goods container warehouse are checked daily and an automatic fire alarm system with a direct connection to the BASF fire brigade additionally guarantees the highest safety standards.

SERVICES

- Handling in and out of storage with IT based storage location management

- Heating/cooling in the hazardous goods container warehouse with temperature monitoring

- Temperature control

- Daily check in the hazardous materials container storage area

INFRASTRUCTURE

- Hazardous materials container warehouse for max. 375 loaded containers

- Storage space for max. 470 TEU empty containers or loaded containers (not hazardous)

- Electrical connections for heating/cooling of containers

- Hot water heater for heating containers up to 75°C

- 1 radio-controlled gantry crane – payload 40 tons

CONTACT

AGENCY SERVICES

ADMINISTRATIVE SERVICES FOR COMBINED TRANSPORT OPERATORS

KTL offers a range of services, including agency services for combined transport operators.

The agency for CT-Operators is based directly at the terminal and serves as an interface between the operator and the terminal. The agency is responsible for processing incoming and outgoing trucks and trains

SERVICES

- Booking, acceptance and issuance of loading units

- Scheduling of CT-trains for maximum capacity

- System based loading of the trains

- Creation of shipping documents for CT-trains

- Creation documents for railway operators

- Creation an application for a claims report

- Contactless handling “KLA” for drivers to optimize dispatch and shorten the terminal round trip times

CONTACT

TECHNICAL SERVICES

TESTING, MAINTENANCE AND REPAIR AT KTL

KTL has its own maintenance management, with focus on the two areas:

CRANE SYSTEMS

- Repair and maintenance of the gantry cranes

CONTACT

Bernd Eberhard

Teamleader Maintenance and repair for Crane Systems

FLEET AND MAINTENANCE MANAGEMENT

- Repair and maintenance of the camera gates (road and rail)

- Maintenance of commercial vehicles (road traffic) and terminal vehicles (terminal trucks / rolling platforms)

- Check and repair of loading units

- Testing, maintenance and repair of the technical equipment and resources

CONTACT

Manuel Meder

Tech. Fleetmanager & Teamleader maintenance and repair